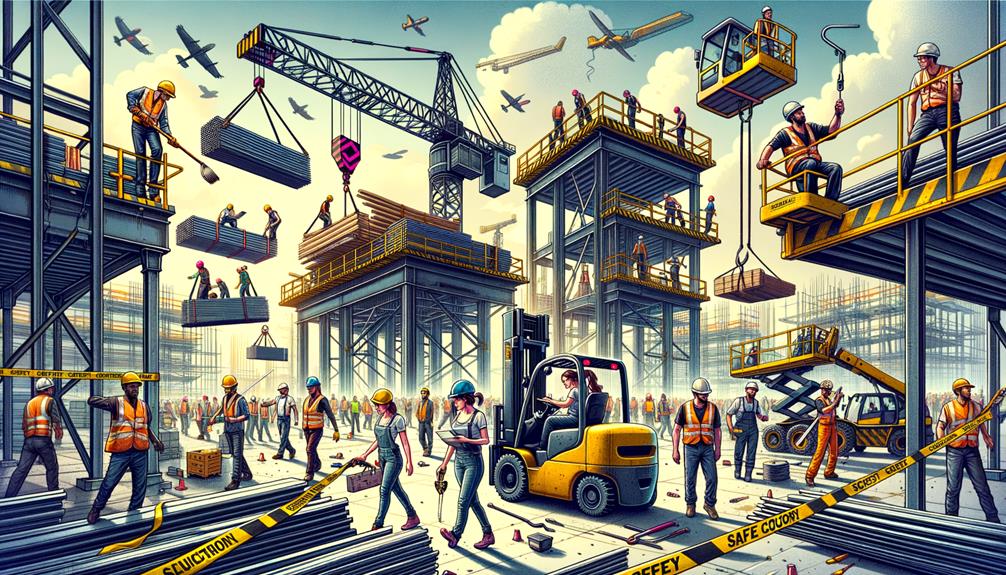

Proper handling techniques are vital in the workplace, as they help reduce the risk of injuries, particularly back injuries and musculoskeletal disorders. Before lifting, it's crucial to assess the load requirements and plan the route to avoid overexertion and ensure stability. Good communication and teamwork also play a key role in minimizing injury risks. Safe lifting techniques and the use of equipment like trolleys and mechanical aids can further reduce the risk of injury. Regular maintenance and safety checks of equipment are also critical for reliable operations. Continuous training and education help develop a strong safety culture, which not only reduces risks but also boosts productivity and well-being in the workplace.

Key Takeaways

When handling heavy loads, it's crucial to assess the weight and size to avoid overexertion and potential injuries. Clear the route of any obstacles or hazards that could interfere with lifting. To lift safely, maintain proper posture by bending at the knees and keeping your back straight. Using lifting aids like trolleys and hoists can reduce the physical strain. Regular training on manual handling is vital to ensure safety and compliance in the workplace.

Importance of Proper Handling

Proper handling techniques are vital in reducing workplace injuries and ensuring employee well-being. The high incidence of back injuries and musculoskeletal disorders (MSDs) linked to manual handling highlights the need for safe lifting practices. Improper handling techniques account for around 40% of workplace injuries, emphasizing the importance of proper posture and safe lifting methods.

To lift safely, I maintain close contact with the load, keeping it hugged towards my body. This approach minimizes strain on my back and other muscles, reducing the risk of injuries. Proper posture is crucial; I keep my back straight and bend at the knees to distribute the stress more evenly across my body.

Musculoskeletal disorders resulting from poor handling practices not only cause personal discomfort but also lead to significant productivity losses. In 2016-2017, MSDs accounted for 35% of lost working days, a substantial impact on any organization. Furthermore, the prevalence of back pain and related disorders means that a significant portion of NHS sickness absence is due to these preventable injuries. Adopting safe manual handling techniques is a crucial step towards safeguarding both my health and professional freedom.

Planning and Preparation

When handling tasks, I start by assessing the load requirements to determine the safest lifting techniques. Next, I inspect the route and surroundings to identify any obstacles that could hinder the process. Finally, I brief the team on their roles, ensuring we're all on the same page and can work efficiently together.

Assess Load Requirements

Evaluating load requirements starts with a thorough assessment of the weight, stability, and potential obstacles surrounding the load. This step is critical for ensuring safe handling and minimizing risks.

First, I need to determine the accurate weight of the load. Misjudging the weight can lead to overexertion and injuries. In many cases, incorporating lifting aids or assistance is necessary, especially for heavier loads.

Stability is another key consideration. An unstable load can shift unexpectedly, causing accidents. To mitigate this, I might need to break down the load into smaller, more manageable segments. This approach reduces the strain and enhances control during the lift.

Identifying any obstacles in the surrounding area is also crucial. Obstacles can hinder movement and increase the risk of accidents. By recognizing these challenges early, I can plan a safer handling strategy.

To assess load requirements, I follow these key steps:

Assess the load's weight to determine if lifting aids or assistance are necessary.

Evaluate load stability and consider breaking it down into smaller segments to enhance control.

Check for obstacles that could impede movement.

Plan a safe and efficient handling strategy based on the assessment.

Proper planning and preparation prevent overexertion and workplace injuries, resulting in a safer and more efficient work environment.

Route and Obstacle Check

Before I start lifting, I take a close look at the route to identify any potential obstacles that could get in the way. This step is critical for assessing risks and preventing accidents. By planning the route carefully, I make sure the lifting area is clear of hazards like loose objects or slippery surfaces that could compromise safety.

The importance of preparation cannot be overstated. According to statistics, overexertion involving outside sources, including lifting, accounted for approximately 31% of non-fatal work injuries in 2019. This highlights the need for thorough planning and obstacle removal to prevent injuries. By prioritizing injury prevention, I contribute to a safer work environment where safety is paramount.

During the risk assessment, I thoroughly examine the surroundings, looking for any obstacles that could hinder the lifting process. This includes not just the immediate lifting area but also the entire path the load will travel. By ensuring the route is clear and secure, I reduce the likelihood of incidents, fostering an efficient and hazard-free operation. This proactive approach is vital for maintaining both safety and productivity in any lifting task.

Team Coordination Plan

A team coordination plan is vital for ensuring efficient and safe manual handling operations. By strategizing and delegating tasks, we can optimize lifting procedures and reduce the risk of injuries. This plan guarantees that every team member understands their role and responsibilities, facilitating clear communication and seamless execution.

Preparation is key to success. It involves evaluating risks, identifying potential hazards, and implementing necessary safety measures. Regular team training is crucial to keep everyone updated on the latest manual handling techniques and safety protocols. This continuous learning process enhances our ability to work together and reduces the likelihood of accidents.

When developing a team coordination plan, consider the following critical elements:

- Risk Evaluation: Identify and evaluate potential hazards associated with the manual handling tasks.

- Clear Roles and Responsibilities: Assign specific tasks to each team member, ensuring everyone knows their duties.

- Communication Protocols: Establish clear channels for communication to facilitate coordination and immediate response to any issues.

- Regular Training Sessions: Conduct training to keep the team informed about best practices in lifting and safety procedures.

Safe Lifting Techniques

Implementing safe lifting techniques is crucial in minimizing the risk of workplace injuries and complying with safety regulations. In healthcare settings, safe patient handling is vital. Healthcare workers must receive thorough manual handling training to prevent injuries, particularly to the lower back. Good manual handling techniques start with planning the lift, assessing the load and environment, and using proper form – keeping the back straight, bending at the knees, and lifting with the legs.

Overexertion and repetitive motions are common causes of injury, making it necessary to incorporate these practices into daily routines. Regular risk assessments help identify potential hazards and ensure compliance with regulations like the Health and Safety at Work Act. Using lifting equipment, such as handling belts and turning aids, can significantly enhance safety. However, proper training and technique remain vital.

Incorporating these measures not only protects healthcare workers but also ensures patient safety and comfort. As healthcare professionals, our commitment to continuous training and adherence to safe lifting protocols is key to creating a safe working environment. By prioritizing these practices, we can reduce injury risks and promote a culture of safety and efficiency.

Using Lifting Equipment

When using lifting equipment, I make sure to understand the different types of lifting aids available, such as jacks, barrows, and trolleys. It's crucial that employees receive proper training on these devices to minimize risks. Regular maintenance and safety checks are also vital in maintaining a safe workplace environment.

Types of Lifting Aids

Using various lifting aids like lifts, jacks, trolleys, and barrows can greatly improve workplace safety and efficiency. By incorporating these mechanical aids, we reduce the physical strain associated with manual handling, creating a safer work environment. Manual handling can often lead to injuries if not managed properly, but with lifting aids, we minimize these risks and promote safe handling practices.

There are different types of lifting aids, each designed for specific tasks:

Lifts are perfect for raising heavy loads to higher elevations, ensuring minimal physical exertion.

Jacks are useful for lifting items a short distance off the ground, typically for maintenance or repositioning.

Trolleys are efficient for transporting heavy items across short to medium distances within a facility.

Barrows are suitable for maneuvering bulk materials, providing stability and ease of movement.

Training for Equipment Use

Proper training on lifting equipment is vital to ensure employees can operate these aids safely and effectively. When workers understand how to use lifting aids like lifts, jacks, and trolleys correctly, workplace injuries, particularly those related to manual lifting, decrease significantly. Training isn't just about meeting regulations; it's a proactive measure that protects health and safety.

By teaching employees the correct techniques, we can prevent musculoskeletal disorders that often result from overexertion and improper handling. These disorders affect not only individual well-being but also lead to reduced productivity and increased absenteeism. Therefore, investing in thorough training programs is crucial.

Employees trained in using lifting equipment can execute tasks more efficiently, reducing strain and minimizing the likelihood of accidents. This training should cover the correct operation of all lifting aids, highlighting techniques that reduce risks associated with manual lifting. While maintenance and inspection of equipment are important, they should be addressed separately.

Ultimately, proper training creates a safer workplace environment and empowers employees. By prioritizing health and safety through effective training, we can ensure a more productive and injury-free workplace.

Maintenance and Safety Checks

While training employees to operate lifting equipment is crucial, maintaining and conducting regular safety checks is equally vital to ensure ongoing operational safety. Regular maintenance ensures our equipment operates efficiently and complies with health and safety standards. Conducting thorough risk assessments and adhering to equipment regulations are key to preventing workplace injuries.

Before each use, safety checks should be performed to identify potential issues or defects. This proactive approach minimizes risks and ensures any signs of wear and tear are addressed promptly. Following manufacturer guidelines for maintenance and safety checks is crucial for optimal performance and equipment longevity.

An ergonomic approach to handling lifting equipment not only enhances efficiency but also reduces the likelihood of injuries. Safety training should emphasize the importance of regular inspections and proper maintenance routines.

Key steps for maintaining and conducting safety checks include:

- Daily inspections to identify visible issues.

- Scheduled maintenance based on manufacturer recommendations.

- Documentation of all inspections and repairs.

- Training updates to ensure all employees are informed of the latest safety protocols.

Avoiding Common Mistakes

Many workplace injuries are caused by overexertion and repetitive motions, making proper handling techniques crucial. In industries where lifting and moving are frequent, such as health and social care, improper techniques can lead to serious musculoskeletal disorders.

To minimize the risk of injury, it's vital to lift correctly. This means keeping the load close to your body before lifting, which reduces strain on your back. Some workers rely too heavily on back belts, which can create a false sense of security and lead them to lift heavier loads than they should.

Proper training in ergonomic lifting techniques is also essential. This training should focus on bending at the knees, not the waist, and keeping the back straight while lifting. Using mechanical lifting aids, such as hoists and trolleys, can also significantly reduce the risks associated with manual handling tasks.

Continuous Training and Education

Regularly updating employees' knowledge through continuous training and education significantly reduces the risk of workplace injuries. By keeping everyone informed about the latest safe lifting techniques, we decrease the occurrence of musculoskeletal disorders. Continuous training in manual handling not only improves safety and health but also boosts productivity by minimizing absenteeism and lost working days.

Continuous education on handling techniques ensures that employees stay up-to-date with the best practices for manual handling. This proactive approach creates a culture of safety in the workplace, empowering employees to work confidently and safely. The benefits of continuous training include:

- Reduced workplace injuries: Regular reinforcement of safe lifting techniques lowers injury rates.

- Increased productivity: Fewer injuries mean fewer disruptions and higher efficiency.

- Improved employee well-being: Ongoing education promotes better health and reduces stress related to manual handling tasks.

- Stronger safety culture: A well-informed workforce is more likely to follow safety protocols, creating an environment where safety is a shared priority.

Investing in continuous training programs is vital for maintaining a strong knowledge base among employees and ensuring a safe and healthy workplace. This commitment to education is crucial for both individual and organizational well-being.

Frequently Asked Questions

What Are the 6 Safe Manual Handling Techniques?

The six safe manual handling techniques are planning the lift, positioning your feet for stability, maintaining good posture, using a firm grip, lifting smoothly without jerking, and avoiding twisting movements. These steps help prevent injuries and promote a safer workplace.

What Are the 5 Types of Manual Handling Tasks?

Manual handling tasks can be hazardous, with 30% of workplace injuries attributed to them. There are five types of manual handling tasks: lifting, lowering, pushing, pulling, and carrying objects. Recognizing these types is crucial to preventing injuries and working safely.

What Are the 5 Steps of Manual Handling?

The 5 steps of manual handling are checking the task, evaluating individual capability, examining load characteristics, considering the working environment, and employing proper handling techniques. By following these steps, you can ensure safety and efficiency, preventing workplace injuries and promoting freedom of movement.

What Are the 8 Safe Handling Procedures?

I follow eight safe handling procedures to prevent injuries: plan the lift, use the right equipment, maintain good posture, keep the load close, avoid twisting, lower carefully, take breaks, and push into place.